Color Coated Galvanized Steel Coil PPGI

Classification :

Chat with us now for a quick response.

Get expert sales advice within 12 hours.

PRODUCT DETAILS

Color Coated Galvanized Steel Coil PPGI Description

PPGI coil is a popular material. It is based on hot-dip galvanized steel sheet or electro-galvanized steel sheet (galvanized layer) and is coated with multiple organic coatings to prevent it from rusting. Used for roof panels, wall panels, furniture, household appliances, auto parts, etc. It maintains the strength of galvanized steel, while its organic coating provides a variety of colors and attractive appearance.

In the construction and manufacturing industries, the Color Coated Galvanized Steel Coil PPGI, has been making a significant impact.

Color Coated Galvanized Steel Coil PPGI is a type of steel coil that combines the strength of galvanized steel with the aesthetic appeal of a color coating. The galvanization process involves coating the steel with zinc, which provides excellent corrosion resistance. This is crucial as it protects the steel from rust and other forms of degradation, especially in outdoor and high - humidity environments.

The color coating on the PPGI adds another layer of functionality and visual allure. It comes in a wide range of colors, allowing architects, builders, and designers to choose the perfect hue to match their aesthetic vision. Whether it's for a modern industrial building, a residential complex, or a commercial structure, the color options of PPGI can enhance the overall appearance.

One of the main advantages of PPGI is its versatility. It can be used in various applications within the construction field. For roofing, PPGI is a popular choice. Its durability ensures that roofs can withstand harsh weather conditions such as rain, snow, and strong winds for years without significant deterioration. The color coating also helps in reflecting sunlight, which can contribute to energy - efficient building design by reducing the need for excessive air - conditioning during hot summers.

In the manufacturing of siding panels, PPGI is also highly sought - after. The smooth and even color coating gives a clean and professional look to the building exteriors. It is easy to install, which helps to speed up construction projects and reduce labor costs.

Another area where PPGI shines is in the production of pre - fabricated structures. From storage sheds to modular homes, PPGI provides a cost - effective and reliable material option. The steel coil's strength allows for the creation of sturdy structures, while the color coating makes them more visually appealing and less likely to require frequent repainting.

Manufacturers of PPGI are constantly improving the product. They are using advanced coating technologies to ensure better adhesion of the color layer, increasing its scratch resistance and long - term color retention. This means that buildings using PPGI will maintain their fresh and vibrant appearance for a longer period.

In addition, the sustainability aspect of PPGI cannot be ignored. Galvanized steel is recyclable, and the production process of PPGI is becoming more energy - efficient over time. This makes it an environmentally friendly choice for construction projects that are increasingly aiming for green building certifications.

The global market for PPGI has been growing steadily. With the continuous development of infrastructure in emerging economies and the trend towards more aesthetically pleasing and durable building materials in developed countries, the demand for Color Coated Galvanized Steel Coil PPGI is expected to rise even further in the coming years.

Product Parameters

|

Product Name |

Color Coated Galvanized Steel Coil PPGI |

|

Thickness |

0.13mm-0.8mm |

|

Width |

600mm-1250mm |

|

Length |

Support Customization |

|

Color |

According RAL Color Card (Can provide custom pattern) |

|

Paint |

PE, SMP, HDP, PVDF |

|

Primer |

Epoxy primer, Polyester primer, Water soluble acrylic primer, Polyurethane primer |

|

Coating Thickness |

Top Coat: 10-30mic, Back Paint: 5-25mic |

Hot Dip Galvanized PPGI Steel

Mainly use hot-dip galvanized steel sheet as the substrate, due to the protection of zinc layer and organic coating, its service life is longer than hot-dip galvanized sheet. The available zinc layer is 275g/m2.

Electro-galvanized PPGI Steel

An electrogalvanized sheet was used as the substrate. Because the zinc layer of electrogalvanized sheet is thin, usually 20g/㎡, its corrosion resistance is not as good as that of hot-dip galvanized sheet. Therefore, the product is not suitable for making outdoor walls and roofs. But it has a beautiful appearance and excellent processing performance, mainly used for home appliances, steel furniture, interior decoration, etc.

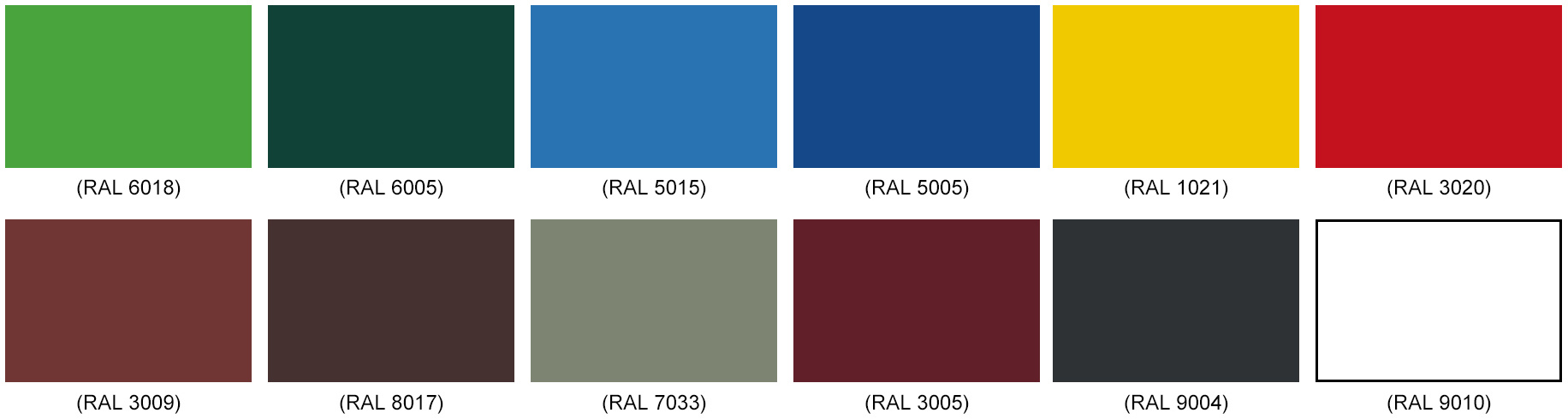

Color Selection

We provide many colors to choose from, the following are common colors, if you like other colors or patterns, please send us the RAL color code.

PPGI Color Coating Coil Advantages

Color coated galvanized coil has a variety of colors and patterns to meet different styles and uses. The colorful coating also makes PPGI steel more resistant to corrosion and durable. PPGI steel coil has excellent processing performance. So you can make the coil into different products according to your needs. The color coated galvanized steel coil also retains the strength of the steel, making it tough and safe. The PPGI coated coil is light in weight and easy to transport and install. Compared with PPGL steel, the price is more affordable.

Surface Treatment

Laminated Film

The process is to coat a transparent organic film (30-50 µm) on the steel coil at high temperature. It has some unique properties, such as fire resistance, fingerprint resistance, excellent durability, anti-fouling ability, etc. Obviously, this treatment method can protect the steel coil well during storage and transportation.

Embossing

Embossed PPGI steel coil design has different patterns. Popular patterns are stucco, rhombus, etc. And it's customizable. Compared with the smooth steel coil, it has a vivid 3D effect.

Coating Type

In the coil coating, the durability of the role is the resin and pigment, the most commonly used finish polyester, silicon modified polyester, high durability polyester and polyvinylidene fluoride.

Polyester PE

Good adhesion, rich color, wide range in formability and outdoor durability, medium chemical resistance, low cost.

Silicon Modified Polyester SMP

The hardness, abrasion resistance and heat resistance of the coating film are good; as well as good external durability and powder resistance, gloss retention, general flexibility and medium cost.

High Durability Polyester HDP

Excellent color retention and UV resistance, excellent outdoor durability and chalking resistance, good film adhesion, rich color, excellent cost performance.

Polyvinylidene Fluoride PVDF

Excellent color retention and UV resistance, excellent outdoor durability and chalking resistance, excellent solvent resistance, good formability, dirt resistance, limited color, and high cost.

Scope of Application

Construction industry: such as roof, interior and exterior wall panels, balcony panels, suspended ceilings, partition walls, windows, door panels, etc.

Transportation: For example, car trim panels, train or ship decks, containers, etc.

Electrical equipment: mainly used for making freezers, washing machines, air conditioners and other enclosures. PPGI coils for home appliances have the best quality and the highest production requirements.

Furniture: such as wardrobes, lockers, radiators, lampshades, tables, beds, bookcases, shelves, etc.

Other industries: such as roller shutters, billboards, traffic signs, elevators, whiteboards, etc.

Packing and delivery

We can provide,

wooden pallet packaging,

Wooden packing,

Steel strapping packaging,

Plastic packaging and other packaging methods.

We are willing to package and ship products according to the weight, specifications, materials, economic costs and customer requirements.

We can provide container or bulk transportation, road, rail or inland waterway and other land transportation methods for export. Of course, if there are special requirements, we can also use air transportation.

PRODUCT TESTING

Our factory products comply with CE/EN10204/ASTM/classification society certificates/CASO/BIS and other certificates, and all orders are subject to TPI (SGS/TUV/BV, etc.) inspection

application area

It has more than 400 supply chain factories with production capacity reserves, 6 large-scale modern warehousing matrices, 1,000 standardized application scenarios, and a complete technical white paper on the entire metal material industry chain accumulated in 10 years.

CUSTOMER VISIT

Wuxi Laiyuan has been conduction extensive and friendly cooperation with domestic and overseas company.on the basis of diversified products, superior quality, reasonable price and thoughtful service.Praised by customers at home and abroad

CHAT SCREENSHOT

An international group company with a comprehensive metal raw material supply chain covering the entire industrial chain of metal materials.

HONOR

Partner

FAQ

Q1:Can I get samples before order ?

Q2:Can I go to your factory to visit?

Q3:How can I get a quotation from you ?

Q4:What product information do I need to provide?

Q5:Does the product have quality inspection before loading?

Q6:How can you guarantee the quantity and how can we trust your company ?

Q7: Do you accept customized orders?

Q8:How long does your delivery time take?

Q9:How many countries you already exported to?

RELATED PRODUCTS

GET A FREE QUOTE